TPI Injection Moulding

- Home

- / Service /

- Injection Moulding

TPI is an industry leader in the field of injection moulding that can process a wide variety of materials and offer additional post moulding services.

Injection Moulding Company in India

TPI is one of the prominent plastic injection moulding companies in India that caters to the automotive, electrical, appliance and renewable energy industries. Injection Moulding is one of TPI’s primary services. With the combined power of cutting-edge machinery and high-end technology, TPI exceeds customer expectations in terms of quality and delivery time.

The infrastructure of TPI’s plastic injection moulding manufacturing unit includes 14 high-precision, conventional injection moulding machines with a range varying from 50 tons to 650 ton. All machines are supplemented with hopper driers, temperature controllers and hot runners. TPI believes in implementing reliable injection moulding principles with a professionally experienced crew. The facility is equipped to cater to injection moulding production 24/7 throughout the year.

TPI is one of the prominent plastic injection moulding companies in India that caters to the automotive, electrical, appliance and renewable energy industries. Injection Moulding is one of TPI’s primary services. With the combined power of cutting-edge machinery and high-end technology, TPI exceeds customer expectations in terms of quality and delivery time.

The infrastructure of TPI’s plastic injection moulding manufacturing unit includes 14 high-precision, conventional injection moulding machines with a range varying from 50 tons to 650 ton. All machines are supplemented with hopper driers, temperature controllers and hot runners. TPI believes in implementing reliable injection moulding principles with a professionally experienced crew. The facility is equipped to cater to injection moulding production 24/7 throughout the year.

Operational Advantages

- TPI has a wide range of machines from 50 T to 650 T.

- Specialized in Insert moulding.

- Value added post moulding processes such as pad printing, heat transfer printing, machining, and assembling.

- In house tool room to manufacture and maintain moulds.

- Machines are operated and maintained for high productivity.

- Ability to process a large variety of materials.

Materials Utilized in Injection Molding

Common group of thermoplastics that include

High-Density Polyethylene(HDPE) and Low-Density Polyethylene (LDPE).

Auxiliary Equipments

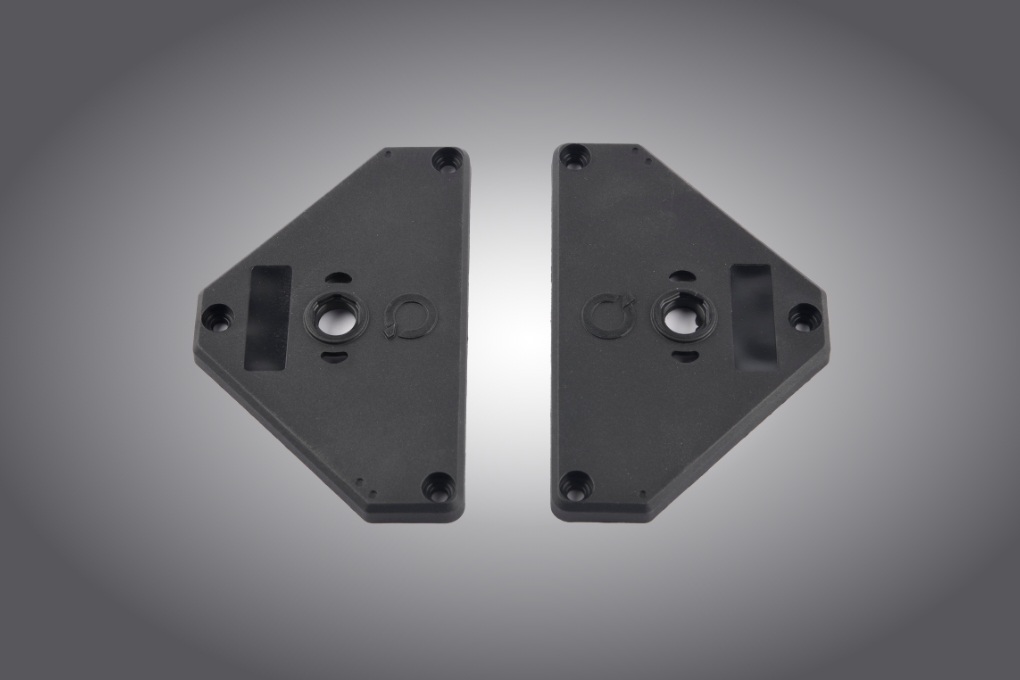

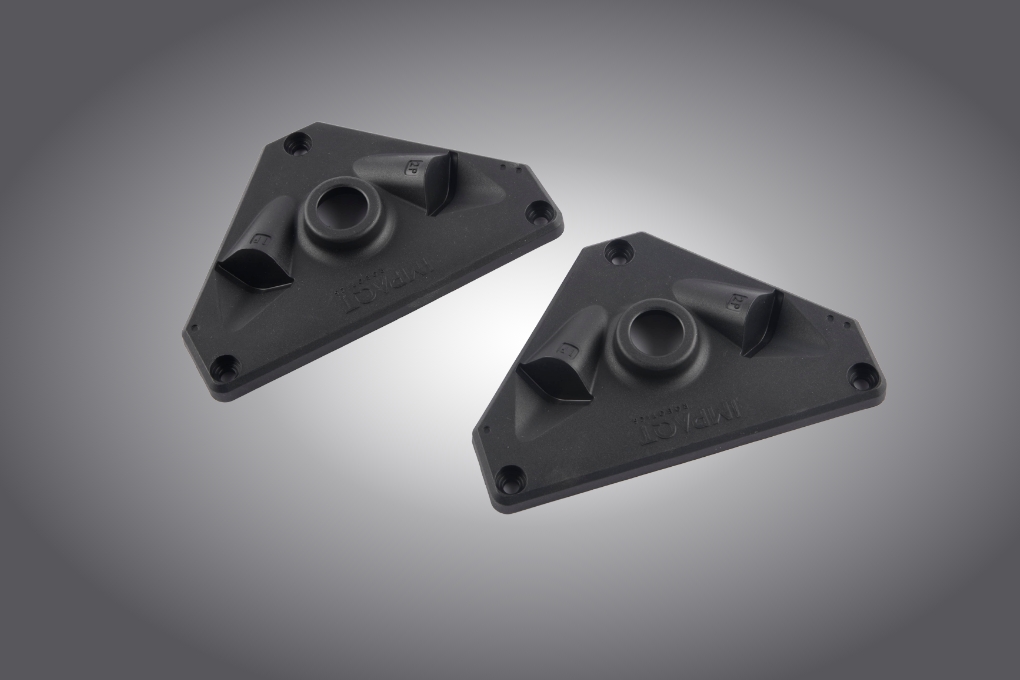

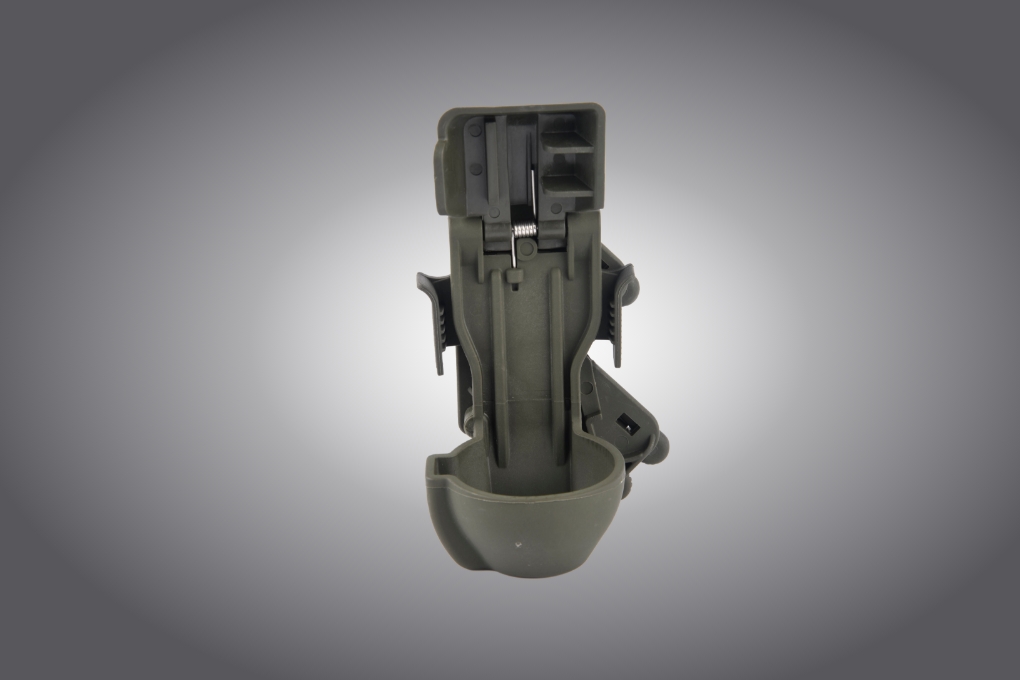

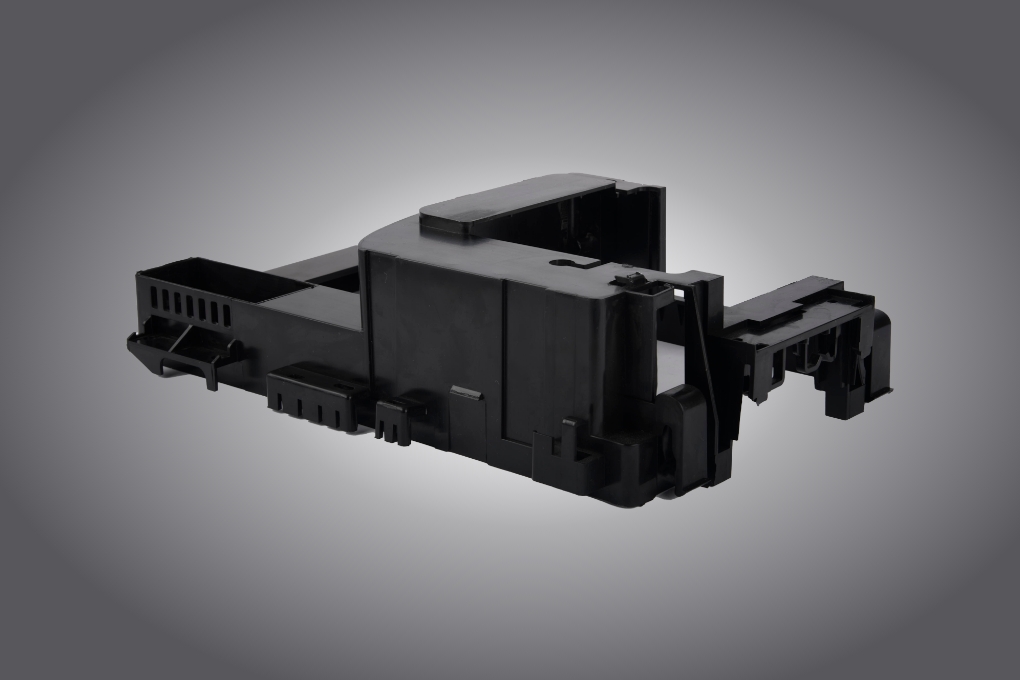

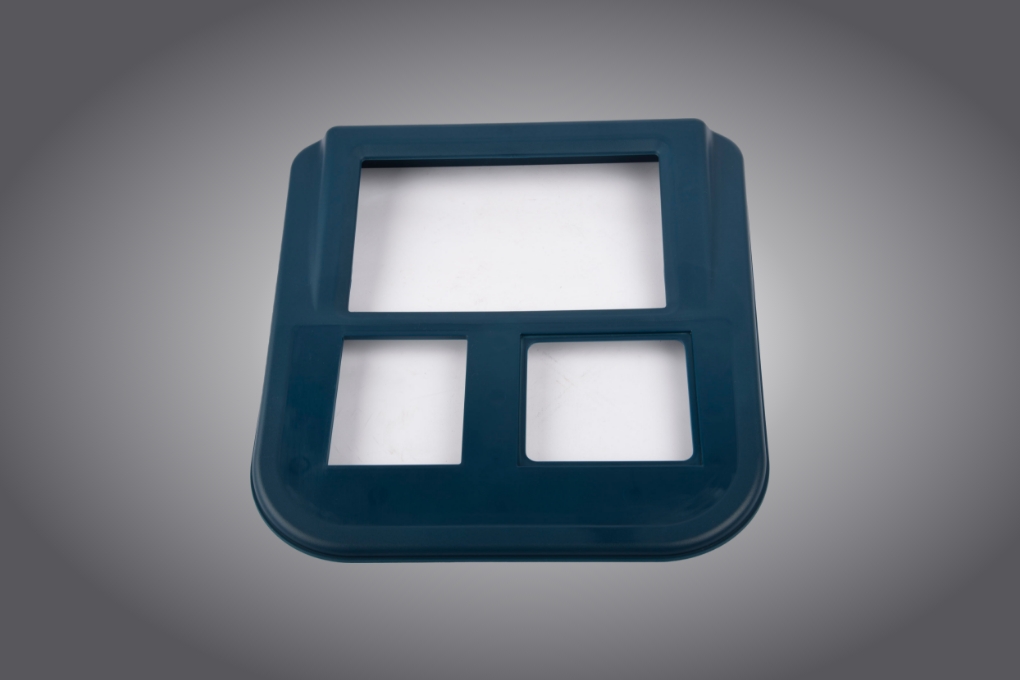

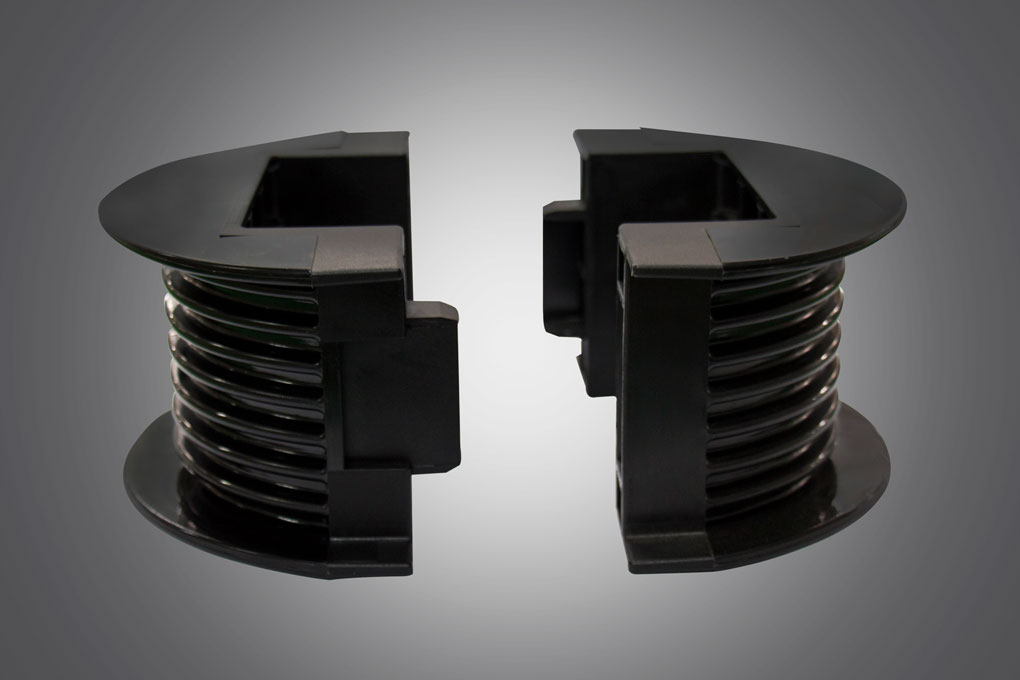

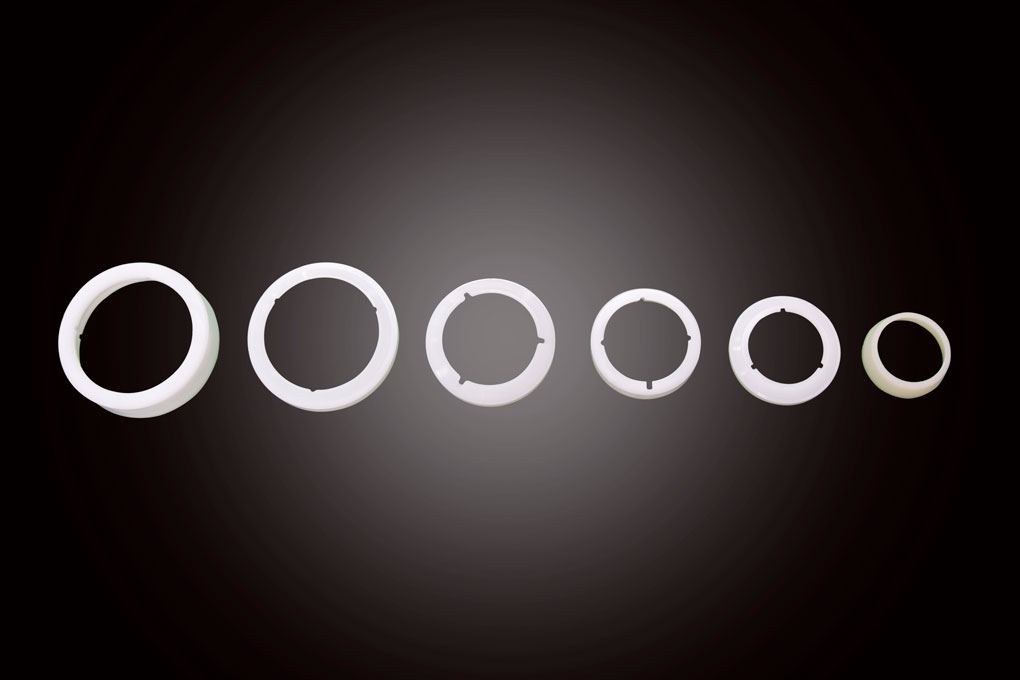

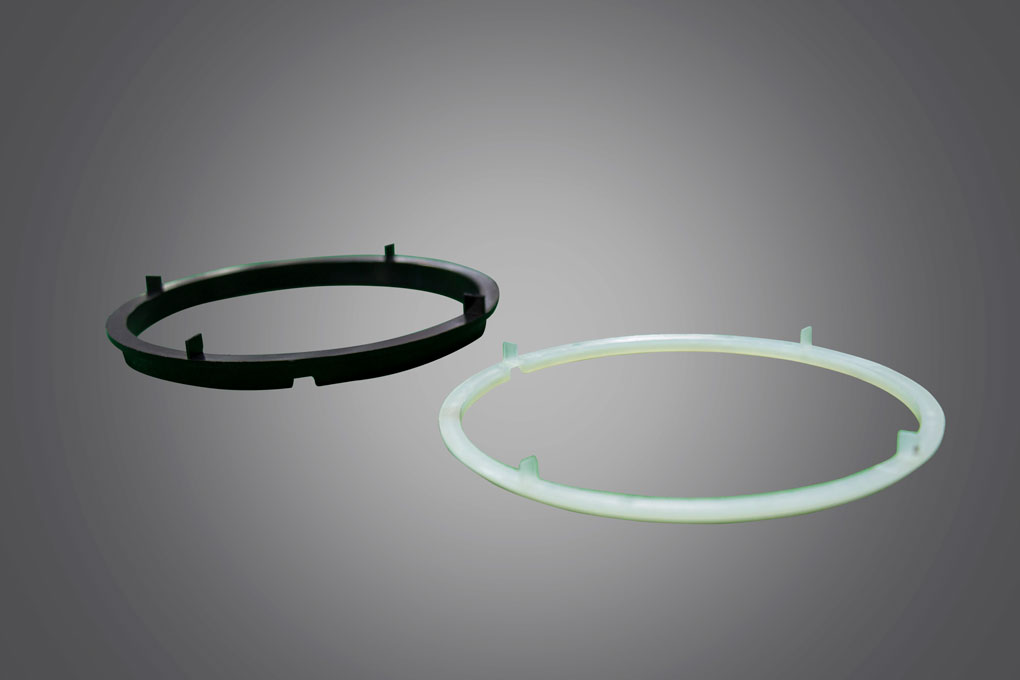

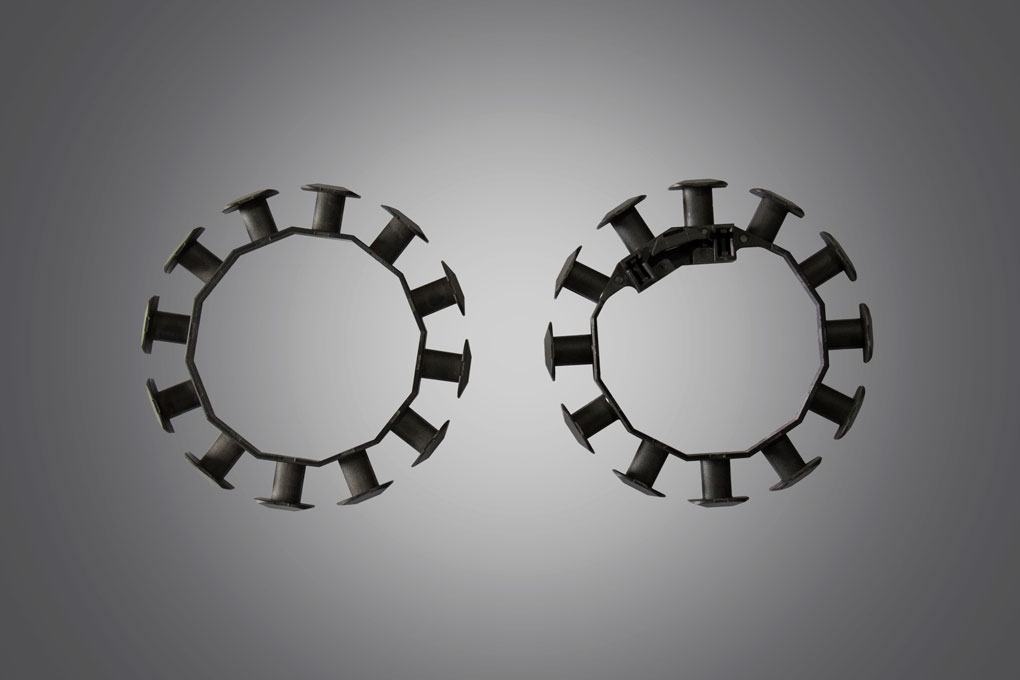

Injection Molding Components Manufactured at TPI

TPI is one of the top plastic moulding companies in India for plastic injection moulding to deliver products that are versatile in function.

Why Injection Molding

- Injection moulding is highly efficient and provides a faster production cycle. The mould’s size and complexity will decide the speed; however, we can achieve anywhere from 15 to 120 seconds in each cycle.

- Offers great design flexibility, as these moulds are subjected to high pressure that results in hard pressing the plastic within the moulds.

- Injection moulding equipment can produce more than thousands of parts resulting in high output even before maintaining the tools used.

- Can produce parts with high tolerance, as the injection moulding process will typically produce parts with +/- 0.200 mm tolerance and at times can achieve tighter tolerances of up to +/- 0.1 mm.

- Provides wide choices of polymer resins and multiple types of plastic materials

- Allows the use of fillers in the moulding material, which adds more strength to the final component.

Talk To The TPI Experts

Want to know more about TPI’s prowess in injection moulding? TPI’s technical experts are ready to talk and initiate a collaboration that will last for years to come.

talk to usReach us

A 21, SIPCOT Industrial Park, Irrungattukottai, Thandalam 55, Kanchipuram Dt. - 602 105, Tamil Nadu, India

call us

+91 9840424173

+91 9840397562

Duns Number

650228575

marketing@techplaastic.com npd@techplaastic.com

Reach out

Get Technical Expertise

TPI strives to keep its customers well-informed about the latest advancements with injection moulding.