compression and transfer moulding.

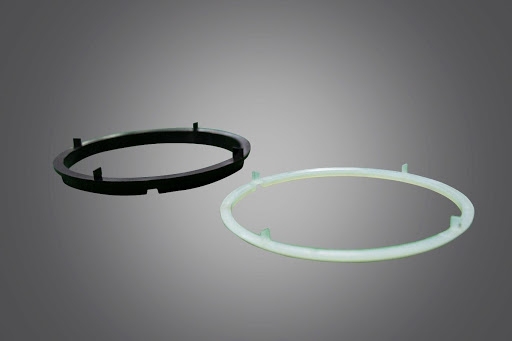

manufacture of injection moulded

components for various industry

segments.

requirements, be it injection,

compression or thermoset injection.

manufacture and qualify moulds

using our inhouse facility and team.

manufacture a range of battery

components.

value-added services (VAS) to validate your

design in a short span of time.

• 3D printing

• Rapid Prototyping

capacity with the addition of HAAS CNC

VMC 3

TPI Advantage

Complete Moulding and Tooling Solutions

At TPI, we offer end-to-end manufacturing solutions — from injection moulding, compression moulding, thermoset injection moulding, to mould design and manufacturing — all in one place. We believe in taking full ownership of every project. Our experienced team manages every stage, from design and engineering to mould qualification and full-scale production of moulds and plastic components. With TPI, you get a single-source partner committed to quality, innovation, and on-time delivery.

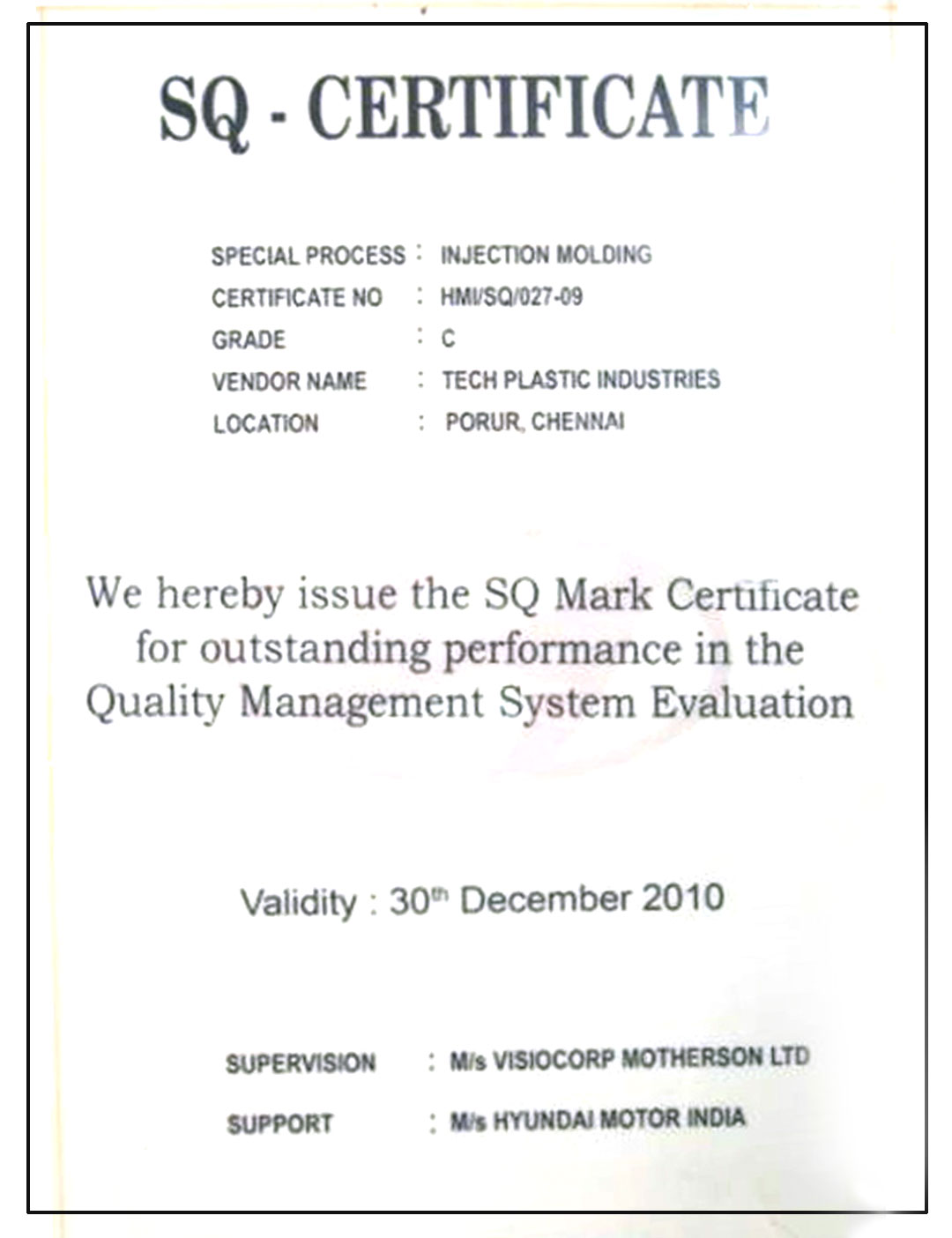

TS 16949, ZED & EMS 140001 Certified

At TPI, we are proud to be one of India's leading IATF/TS 16949-certified moulders, recognized by BVCI. Our certification reflects a strong commitment to developing a process-oriented quality management system that drives continual improvement, defect prevention, and waste reduction across the supply chain. We are dedicated to delivering high-quality products that meet and exceed customer requirements — efficiently and consistently. Further strengthening our commitment to excellence, TPI has been awarded the ZED (Zero Defect, Zero Effect) Certification by the Quality Council of India, recognizing our focus on producing zero-defect products without harming the environment. Our proactive approach to sustainability is reinforced by our EMS 14001 certification, demonstrating our responsibility toward environmental management and sustainable manufacturing practices. When you partner with TPI, you choose a team committed to quality, efficiency, and environmental responsibility at every step.

WIDE RANGE OF MOULDING MACHINES

At TPI, we offer a comprehensive range of injection moulding machines from 50 Tons to 650 Tons, allowing us to manufacture a wide variety of components for complete assembly solutions. All our machines are equipped with hopper dryers, mould temperature controllers, hot runner systems, and other advanced auxiliary equipment to ensure precision moulding and consistent product quality. Our plastic manufacturing facility is supported by captive power generators, ensuring uninterrupted production and reliable fulfillment of customer requirements — even in the toughest conditions. Partner with TPI for scalable, efficient, and high-quality plastic component manufacturing.

IN-HOUSE TOOL ROOM

At TPI, we offer full in-house toolroom capabilities to design and manufacture custom moulds tailored to customer specifications.

We specialize in manufacturing a wide range of complex moulded components, including hot runner moulds, unscrewing moulds, and collapsible core moulds. Each mould is qualified in-house, where our team of experienced quality engineers conducts detailed layout inspections to ensure precision and compliance.

Post-validation, we provide customers with sample components along with complete quality documentation for final approval.

With our integrated toolroom and strict quality control, TPI ensures faster development cycles, reliable performance, and superior part quality for every project.VALUE ADDED SERVICES

At TPI, we offer a range of in-house value-added services to enhance product quality and speed up time-to-market. Our capabilities include rapid prototyping, heat transfer labeling, sealing, post-moulding curing, and more — ensuring every component is production-ready. We specialize in custom 3D printing using advanced technologies like Fused Deposition Modelling (FDM), Stereolithography (SLA), and Multi Jet Fusion (MJF) to support fast development and validation. With TPI, customers receive high-quality plastic components made from premium raw materials, fully finished and ready for assembly, eliminating additional processing and reducing project lead times.

WIDE RANGE OF PLASTICS

TPI has the knowledge and capability of working with both Commodity plastics and Engineering plastics including , Nylon 6/ Nylon 6,6 (Upto 45% GF, UV, FR), PC ABS Alloy, PMMA, Polycarbonate FR/ UV, ABS - Food Grade. (FDA approved), TPE, TPU, Delrin, PBT PPS, PC Lexan 9134P, PP, LDPE, HDPE

Industries Served

One of the best plastic moulding & tooling companies in India, working as a trusted Plastic Moulding Partner Across Sectors

As one of the leading plastic moulding companies in India, TPI delivers high-quality, cost-effective plastic components to a wide range of industries using advanced manufacturing technologies.

Our rapid manufacturing capabilities and focus on precision engineering have made Tech Plaastic Industrie a trusted partner for companies across automotive, electrical, industrial, consumer goods, and healthcare sectors.

With a strong commitment to quality, speed, and affordability, TPI continues to pioneer the manufacturing of plastic components that meet the evolving needs of diverse industries in India and beyond.

Customer service, unwavering commitment to quality and accountability are TPI’s core values!

About UsOUR VISION

To retain and expand clientele base with consistency in quality, service excellence, competitive pricing, and foster a long-term customer relationship

OUR MISSION

To pursue excellence in delivering superior quality products, in adopting top-notch manufacturing processes and in providing workforce training of international standards.

VALUES

Values built on the foundation of customer service, satisfaction, unwavering commitment, accountability, professionalism, and consistent growth of stakeholders.

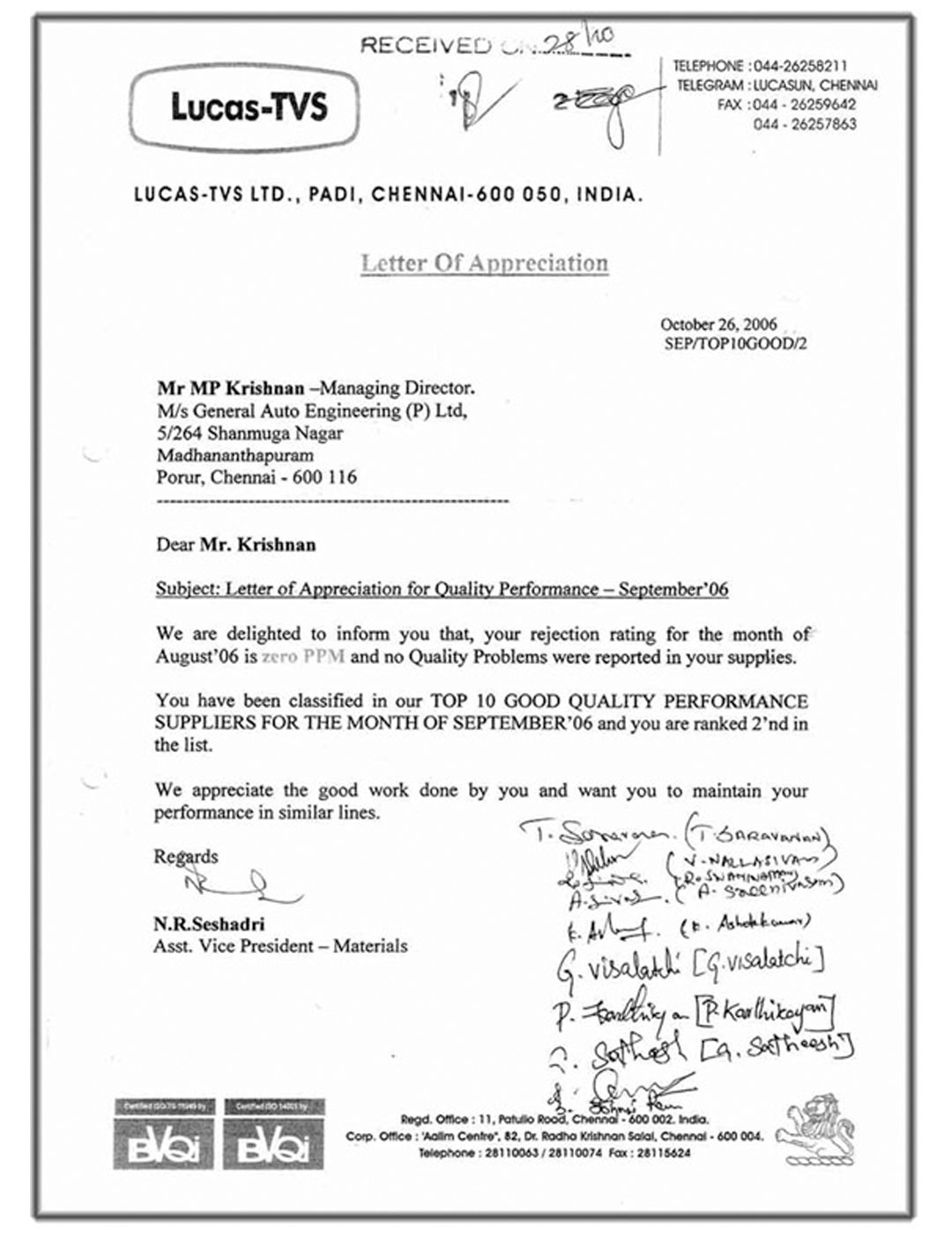

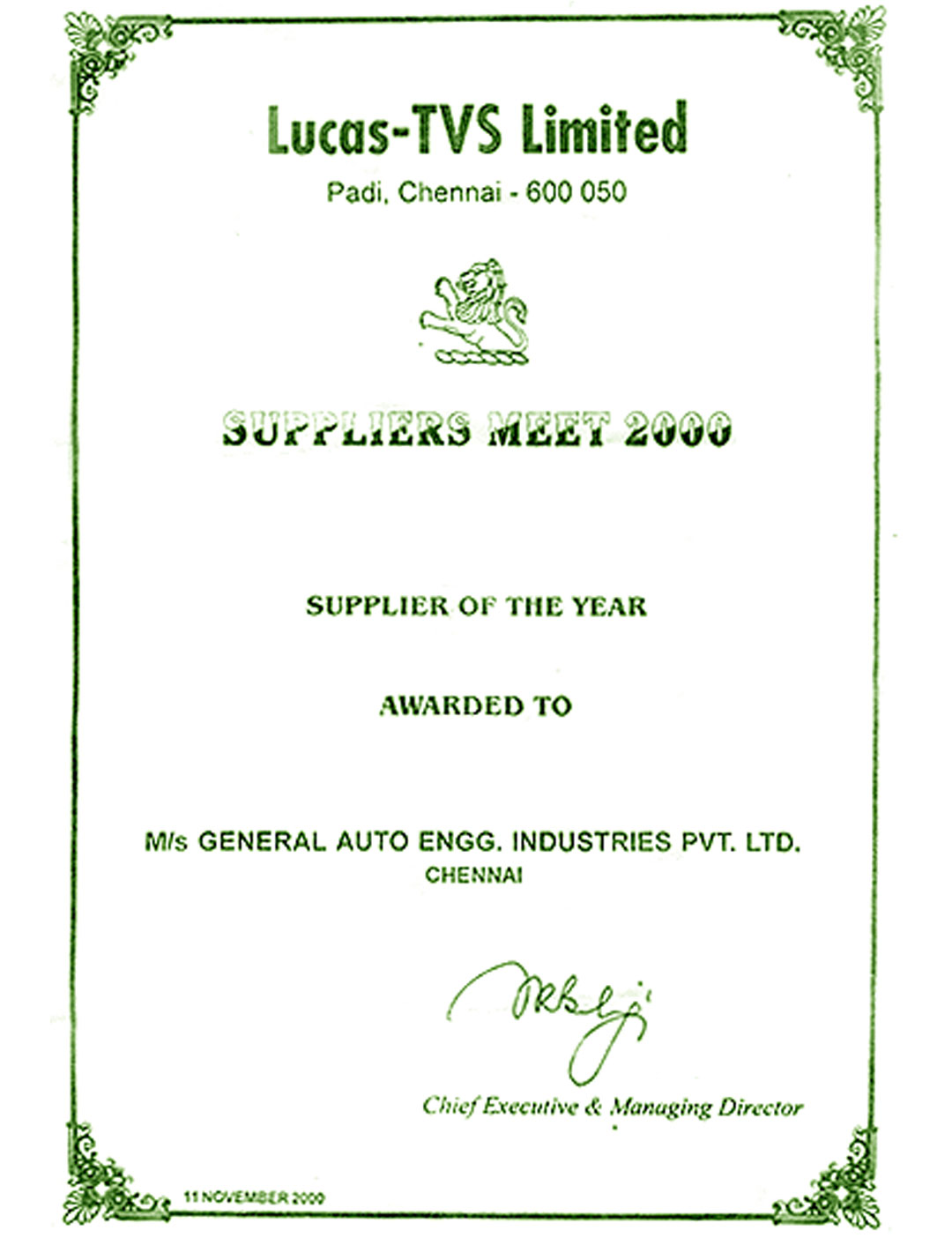

Awards and Recognition

Honours received for consistent quality in Plastic Moulding manufacturing capabilities

Reach us

A 21, SIPCOT Industrial Park, Irrungattukottai, Thandalam 55, Kanchipuram Dt. - 602 105, Tamil Nadu, India

call us

+91 9840424173

+91 9840397562

Duns Number

650228575

marketing@techplaastic.com npd@techplaastic.com

Let’s Connect

Let’s Collaborate

We are just a click away! Leave your contact details, and our

team will get back to you!

Promising Excellence

At TPI, our experience and expertise ensure a seamless, hassle-free collaboration and flawless service delivery — all at competitive pricing in India.

Partner with TPI to manufacture your high-quality plastic components with a company where Operational Excellence is at the heart of everything we do.

Case Studies

With our expertise as one of the best plastic moulding companies in India, we solve multiple challenges faced by various industries on a global scale, TPI has evolved and grown to become one of the most trusted names in the industry. TPI has resolved various technical hurdles across industrial sectors spanning over the USA, Australia, Japan, Namibia, Germany, and France.